Staggered Truss Steel Framing: A Sweetheart Structural System for Hotels, Condominiums, Dormitories, Apartment Buildings

1. Planet Hollywood, Las Vegas, USA: 39 Storey, 119 m high, Completed 2000

|

Planet Hollywood, Las Vegas, USA |

2. Aladdin Hotel, Las Vegas, USA: 38 Storey, 2600 rooms, floor to floor truss height 9 feet

|

Aladdin Hotel, Las Vegas, USA |

3. Delta Bow Valley Hotel, Calgary, Canada

|

Delta Bow Valley Hotel, Calgary, Canada |

4. Half Moon Harbour Apartments, North Bergen, Newzealand

|

Half Moon Harbour Apartmants, North Bergen |

5. Hartford Marriot Hotel, Cunneticut, USA

|

Hartford Marriot Hotel, Connecticut, USA |

6. Mystic Marriot Hotel & Spa, Connecticut, USA

|

Mystic Marriot Hotel & Spa, Conneticut, USA |

7. Staybridge Suites, Chicago, USA 14 storey steel floors over 4 concrete parking level, floor to floor height 10 feet, total height 186 feet

|

Staybridge Suites, Chicago, USA |

8. Summer House, Stamford, Connecticut, USA 22 Storey, 226 units, 5 level of parking, ground level for retail and restaurants

|

Summer House, Stamford, Conneticut, USA |

- Hocking College Dormitories, Nelsonville, Ohio 2 nos 200 bed each of 45000 sqfeet

- Embassy Suites Hotel, New York City

- Lafayette Place Hotel, Boston

- Resort International Hotel, Atlantic City

- Trump TajMahal, Atlantic City: 42 storey, 131m high, 1971 rooms, completed 1990

- Renaissance Hotel, Nashville

- Towers on the Central Park, New York City, complex of 20 storey and 9 storey, 599 apartments

- Seascape Point Condominium, Osage Beach, Missouri

- Macallen Building Condominium, Boston market, 140 units, completed 2007

- 360 State Street, New Haven, Connecticut

- Clayton Park Apartments, White Plains, New York

|

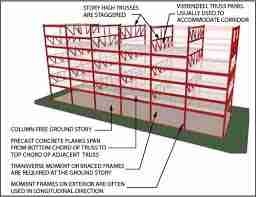

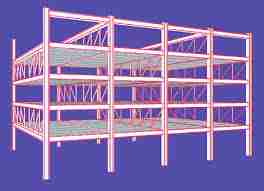

STF Arrangement |

|

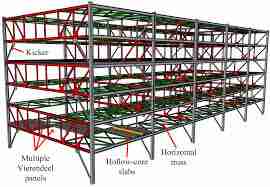

Seismic Horizontal Bracings for STF |

|

Hollow Core Slab/Precast Plank Flooring |

- Large clear span open areas for ballrooms, or other wide concourse are possible at the ground floor level, because columns are located only on the exterior faces of the building and no interrior column inside. This allows for spaces as much as 20 m in each direction (400 m2 free area) with columns often only appearing on the perimeter of a structure. This also increases design flexibility especially for atrium placement and open space floor plans.

- Floor spans may be short bay lengths, while providing two column bay spacing for room arrangements. This results in low floor-to-floor heights. Typically, an 8'-8" floor-to-floor height is achieved. Overall building height is drastically reduced giving economy in HVAC costs too.

- Columns have minimum bending moments due to gravity and wind loads, because of the cantilever action of the double-planar system of framing. It is easy to have full height cantilevered balconies.

- Columns are oriented with their strong axis resisting lateral forces in the longitudinal direction of the building. Plus horizontal bracings are suggested at floor levels for effective seismic load transfer.

- Maximum live load reductions may be realized because tributary areas may be adjusted to suit local code requirements.

- Foundations are on column lines only and may consist of two strip footings. Because the vertical loads are concentrated at a few column points, less foundation cost and formwork is envisaged.

- Drift is small, because the total frame is acting as a stiff truss with direct axial loads only acting in most structural members. Secondary bending occurs only in the virendeel opening/chords of the trusses.

- High strength low alloy steels may be used to advantage, because all truss members and columns are subjected, for all practical purposes, to axial loads only except for virendeel panel (corridor opening)

- A lightweight steel structure is achieved by the use of high strength low alloy steels and an efficient framing system. Since this reduces the weight of the superstructure, there is a substantial cost savings in steelwork and foundation work.

- Faster to erect than comparable concrete structures. Once two floors are erected, window installation can start and stay right behind the steel and floor erection. No time is lost in waiting for other trades, such as bricklayers, to start work. Except for foundations, topping slab, and grouting, all "wet" trades are eliminated. More environment-friendly, no waste, can work in crawled space. trusses are concealed within the vertical deviding walls.

- Fire resistance; steel is localized to the trusses, which only occur at every 58-to-70-feet on a floor, so the fireproofing operation can be completed efficiently. Furthermore, the trusses are typically placed within demising walls and it is possible that the necessary fire rating can be entirely by enclosing the trusses with cement/gypsum wallboard partitions. Finally, if spray-on- protection (cement based vermiculite) is desired, the applied thickness can be kept to a minimum due to the compact nature of the truss elements.

- Early involvement and coordination between architect, MEP, structural is mandetory

- To establish floor to floor height considering all parameters

- Early interactions between fabricators, erectors, qnd Plank suppliers is critical

- For planks and slabs, blockouts and openings for essential services to be precisely done beforehand with proper coordination.

- Headed Stud coordination - when are the put on and welded with steel members

- Precast cambers, Truss cambers, topping slabs as finished floor plus tiles

- Erection sequence of truss particularly when there is a space constraint

- Moment connection plates with precast supplier

- AISC Design Guide 14: Staggered Truss System, 2003

- High-Rise Housing in Steel, the Staggered Truss System, Massachusetts Institute of Technology, Departments of Architecture and Civil Engineering, January 1967.

Recommendation

Comments

Post a Comment