5 Little Known Rules to Design Long Span Cable Stayed Bridges are discussed below. But before we delve into these little known secrets let us see what are the top 12 longest span cable stayed bridges ( carrying automobiles on highways or railways) around the world as of now. Listed below are the top 12 longest cable stayed bridges of the world in ascending order but there is stiff competetion amongst countries to topple one another for the top position. Just see the length of main span constructed so far and opened for traffic as a structural engineering marvel. Surprisingly, China holds the credit of 7 longest span cable stayed bridges in this list of top 12 and dominates the world. Just Google to find out more information about them. Here goes the list of top 12 longest span cable stayed bridges:

12. Jingyue Yangtze Bridge China: Main Span 816m Pylon 285.5m Opened 2010

|

Jingyue Yangtze River Bridge, China |

11. Jiujiang Yangtze Bridge China: Main Span 818m Pylon 242m Opened 2013

|

| Jiujiang Yangtze River Bridge, China |

10. Shishou Yangtze Bridge China: Main Span 820m Pylon 234m & 232m Opened 2019

|

Shishou Yangtze River Bridge, China |

9. Chizhow Yangtze Bridge China: Main Span 828m Pylon 237m & 246m Opened 2019

|

Chizhow Yangtze River Bridge, China |

8. Pont de Normandy Bridge France: Main Span 856m Pylons 214, 277m Opened 1995

|

Pont De Normandi, France |

7. Tatara Bridge Japan: Main Span 890m Pylon 220m Opened 1999

|

Tatara Bridge, Japan |

6. Jiayu Yangtze Bridge China: Main Span 920m Pylon 255.4m Opened 2019

|

Jiayu Yangtze River Bridge, China |

5. Edong Yangtze Bridge China: Main Span 926m Pylon Opened 2010

|

Edong Yangtze River Bridge, China |

4. Stonecutters Bridge Hong Kong (China) Main Span 1018m Pylon 293m Opened 2008

|

Stonecutters Bridge, Hong Kong (China) |

3. Sutong Bridge China: Main Span 1088m Pylon 304.4m Opened 2008

|

Sutong Bridge, China |

2. Hutong Yangtze Bridge China: Main Span 1092m Pylon 325m Opened 2020

|

Hutong Yangtze River bridge, China |

1. Russky Vladivostok Bridge Russia: Main Span 1194m Pylon 320.9m Opened 2012

|

Russky Vladivostok Bridge, Russia |

Cable-stayed bridges may look similar to suspension bridges. They both have roadways that hang from cables and both have towers. But the two bridges support the load of the roadway in very different ways. The difference lies in how the cables are connected to the towers. In suspension bridges, the cables ride freely across the towers, transmitting the load to the anchorages at either end. In cable-stayed bridges, the cables are attached to the towers, which alone bear the load.

Pros and Cons of Cable Stayed Bridge

Pros

- Much greater stiffness than the suspension bridge, so that deformations of the deck under live loads are much reduced.

- Can be constructed by cantilevering out from the tower - the cables act both as temporary and permanent supports to the bridge deck.

- For a symmetrical bridge (spans on either side of the tower are the same), the horizontal forces are balanced and large ground anchorages are not required.

- Can be constructed faster than suspension bridge.

- Requires less cable than suspension bridge.

- Strong against earthquakes, streamlined aerodynamic deck sectionfor less wind effect

- Anchorage requirements are much less than suspension bridge.

Cons

- Vulnerable to the forces of wind because of the cables´s flexibility and inability to handle compression and bending forces effectively during erection due to wind effect.

- Cables are pulling the bridge deck diagonally (mostly due to fleet angle with the horizontal), not directly up, requiring the bridge deck to be stronger to resist the resulting horizontal compression forces.

- Single plane cables are more vulnerable laterally hence require torsion resistant box girder deck

- Vulnerable for sinking of support/foundation at pylons

5 Little Known Rules Regarding the Design of Cable Stayed Bridge

Rule 1: Geometry Optimisation

If Main Span is L, Side Span is Ls and Pylon Height above Deck is h then keep:

- Side Span Ls = 0.3 to 0.4L

- Pylon Height above Deck h = 0.15L to 0.2L; then add deck thickness and navigational clearance for overall height. Choose the type of Pylon as A Frame, H Frame, Inverted Y Frame etc as per techno-proficient system. Get the idea from the images of Pylons from top 12 bridges.

- Rounded edge deck profile is best for mitigating lateral wind effects on bridge

- Cable spacings may be @12m or in multiples of 12m in main span, stay cables are much closer at anchorage. This is done to reduce deck section to make it aerodynamic and streamline in wind.

Rule 2: Loading Optimisation

Dead Load (DL): The length of the span affects the bridge deck requirements; a long span bridge needs a deck with low self weight. The material of deck to be chosen juduciously. Dead loads of wearing coats and crash barriers and other services to be considered. There are three types of decks and their range of selfweight is approximately as below:

- Steel deck 2.5-3.5 kN/m2 => low self-weight which makes it widely used in long span bridges. Though expensive compared to concrete, and yet substantial savings can be achieved for Cables, Pylons, and Foundations. Russky bridge is a good example of using rouned edge steel box girder for tha main span. HSLA steel of higher grades may be used. Generally, this type of steel deck may be prone to vibration/fatigue when DL/LL ratio is < 1

- Steel Concrete Composite deck 6.5-8.5 kN/m2 => Composite deck is a structure with a steel girder and concrete slab, which form a combined structure. Concrete slab can be precast or casted in situ on steel elements. The selfweight of this deck type is lower than the weight of concrete deck. Concrete carries most of the compressive normal force of the deck. Tatara Bridge at Japan and Vidyasagar Setu at India are the finest examples. HSLA steel of higher grades and high strength concrete may be used for deck. Here the DL/LL ratio < 0.5 so vibration and fatigue criteria is much reduced

- Concrete deck 10-15 kN/m2 => Concrete decks can be made of precast elements or they can be cast in place. Because of their high self weight they are suitable for counterweight on side spans with closely spaced cables and also utilised for small or medium spans. The concrete is reinforced or prestressed. The cost of concrete is low but its weight increases the dead load of the bridge thus requiring larger dimensions for cables, pylons, piers and anchorage structures. DL/LL ratio is often < 0.25 thus static analysis may be found sufficient.

- Steel Cables: For economic reasons high strength parallel strand cables are mostly used worldwide today. The corrosion protection for every single strand comprises of any of (i) galvanizing of every single wire in the strand, (ii) filling the interstices between the single wires with grease (iii) surrounding each strand with a directly extruded PE-sheath. Typically, stay cables of a cable stayed bridge are post-tensioned to offset the effect of the bridge dead load.

Live Load (LL): A live load of 4 kN/m2 is recommended for Cable, Pylons, and Foundation design. However, standard axle loads for vehicles (in highways) as per local codes to be considered for design of deck elements. In Parking Structures, the LL is 2.5 kN/m2 that includes trucks and other big vehicles, so 4 kN/m2 is a good assessment of LL on the bridge. According to the CAN/CSA-S6-06 [2006], the magnitude of the live load is equal to 16.2kN/m and 25.2 kN/m for the case of two and four lanes highway loadings, respectively.

Rule 3: Longitudinal Cable Arrangement

There are three configurations to choose from: Fan (Radial) system, Semi-Fan system, Harp System. The cable planes can be Single Plane (Stonecutters Bridge), Double Plane, and Triple Plane (used for much wider deck width)

|

Fig 1: Fan (Radial), Semi-Fan, and Harp Cable Configuration |

Harp System: Harp system: In the harp cable-stayed bridge, cables are connected along the tower and are placed parallel to each othe.The cables are spaced uniformly along the tower height and also along the girder, giving an excellent stiffness for the main span.The connection of the cables to the towers is much easier than in the radial system. Even with the disadvantage of the development of the bending moment, the harp configuration is still very appealing to bridge designers because of its geometrical aesthete. In a double plane cable system, the harp configuration helps minimize the visual intersection of cables from oblique angle.. Studies indicate that Harp system is 8% costlier than Fan system and 22.5% costlier than Semi-Fan system for similar spans. Not a good choice in modern times. Schematically shown in 3rd image of Fig 1

Rule 4: Pylon/Tower Configuration

The Pylon/Tower configurations are: H or Portal Frame, Inverted Y, Inverted Y+D, A Frame, A+D type as shown in the Figure 2 below. Each one of them has certain advantages and disadvantages so to be selected judiciously considering environment, aesthetics, and soil bearing strata.

|

Fig 2: Pylon/Tower Configuration |

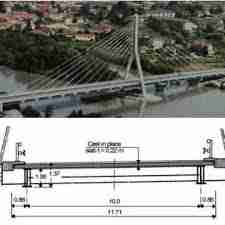

Rule 5: Deck Optimisation

One of the popular systems used in the design and construction of cable-stayed bridges is the composite steel-concrete deck. In this system, the deck consists of two structural steel edge girders connected by transverse steel floor beams and supporting a precast/cast in place reinforced concrete slab.

|

Steel-Concrete Composite Deck |

The advantages of such composite decks are as follows:

- The concrete roadway slab is cheaper than the steel orthotropic deck.

- The precast slab minimizes the redistribution of the compression forces onto the steel girders resulting from shrinkage and creep.

- High resistance against rotation can be achieved by anchoring the stay cables to the outside steel main girders.

- The construction of the relatively light steel girders can be done easily before adding the heavy concrete slab.

- The dead weight of the composite deck is far below that of a concrete deck.

For two lane width. deck depth can be upto 2 m for 12 m cable spacings. For four lane width, deck depth may be 3.5 m for 24m cable spacing. However, aerodynamic geometry at edges are mandetory.

References

- Troitsky M.S., Cable-stayed bridges: theory and design.

- Walther, R., Houriet, B., Isler, W., Moia, P., Klein JF. Cable-stayed bridges.

- Gimsing NJ. Cable Supported Bridges Concept and Design.

- Podolny W, Scalz, J. Construction and Design of Cable-stayed Bridges.

Recommendation

Comments

Post a Comment